Quality

Implement incoming material quality performance. Process inspection. Final quality inspection. Storage and transportation. The whole process of the four major control

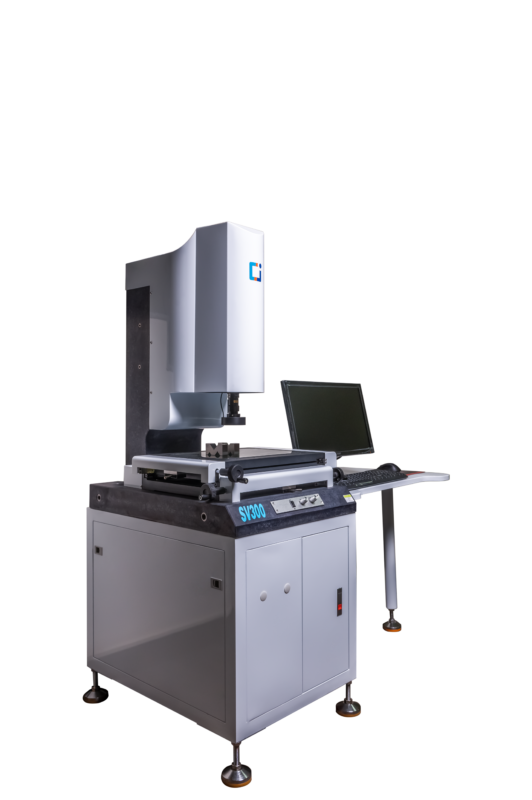

In order to ensure the quality of our customers' products, Torng Yea conducts full process inspection and quality control (IPQC) from the raw material end to the shipping end, including four major quality controls: incoming materials, production process, finished products, and storage and transportation. We conduct rigorous standard checks on the appearance, dimensional accuracy, roughness, hardness, etc. of workpieces to ensure consistent and stable quality of Torng Yea's products, whether parts or finished products.